How to Use AI in Construction: 15 Examples & Benefits

Dec 6, 2024

The construction industry is undergoing a technological revolution, with artificial intelligence (AI) leading the charge. From design and planning to safety and resource management, AI is transforming traditional workflows and introducing efficiencies previously thought impossible. But how exactly is AI shaping the future of construction, and what benefits does it bring?

This blog examines the application of AI in construction, featuring examples that demonstrate its capacity to streamline processes, enhance safety, and drive innovation. Let’s explore how AI-powered tools are redefining every stage of the construction lifecycle.

What Is AI in Construction?

Artificial intelligence (AI) in construction includes a broad range of construction technologies, from machine learning algorithms to advanced robotics, all tailored to revolutionize the industry.

These systems automate processes, enhance decision-making, and boost efficiency at every stage of a construction project—from design and planning to on-site operations and facility management.

The journey of AI in construction has its roots in early technological advancements. In the 1960s, computer-aided design (CAD) laid the groundwork by optimizing construction plans digitally.

By the 1980s, innovations like computer-aided manufacturing (CAM) and computer numerical control (CNC) machines automated the production of building components, streamlining the construction process.

The 2000s marked a turning point as researchers began applying machine learning to predict equipment failures and monitor maintenance needs—an early yet impactful example of AI’s potential in construction.

Fast forward to today, AI adoption is accelerating across the industry. AI-powered tools tackle repetitive and physically demanding tasks, such as bricklaying, painting, and welding, reducing labor costs and speeding up project timelines.

Advanced algorithms analyze real-time data from job sites to identify design flaws, safety hazards, and inefficiencies, enabling proactive responses that save time, money, and lives.

What Are the Benefits of AI in Construction?

Before we go into specific examples of how AI is used in construction, here are a few of the benefits AI provides in the sector:

Generative AI for Design and Planning

According to McKinsey, by 2030, activities that account for up to 30% of hours currently worked across the US economy could be automated—a trend accelerated by generative AI.

Generative AI uses deep learning to analyze vast datasets. This includes blueprints, models, and design parameters, to produce innovative and efficient solutions. Unlike traditional methods, generative AI doesn’t just refine existing ideas—it generates entirely new designs tailored to specific requirements.

One of its most impactful applications is in 3D design and planning. Generative AI seamlessly integrates architecture, engineering, and specialized systems like electrical and plumbing into cohesive building models.

By leveraging AI-powered generative design, construction teams can anticipate and resolve potential clashes between various design elements early in the planning phase. This proactive approach minimizes costly rework and ensures smoother project execution.

Beyond design, generative AI opens new possibilities in construction by enabling the creation of advanced simulations and predictive models. For example, it can generate virtual prototypes that test how a structure might respond to environmental conditions, ensuring resilience and sustainability.

“I believe in 2024, we will see AI increasingly used in in the construction industry. Regenerative design/optimization will be one way. As design teams set parameters required on their designs and AI tools are used to create various simulations of the form and shape infrastructure or buildings will take or design teams use AI tools to solve complex infrastructure problems that require optimization of various parameters.”

—James Niyonkuru Bicamumpaka, Sr. Project Engineer, Webcor Builders

Internet of Things (IoT) for Real-Time Data

The Internet of Things (IoT) refers to physical objects embedded with sensors, software, and connectivity technologies that enable them to communicate and exchange data with other systems over networks.

In construction, IoT is transforming how projects are managed by providing real-time data and insights that improve efficiency, safety, and decision-making.

IoT applications in construction include smart sensors for tracking equipment performance, monitoring environmental conditions, and ensuring worker safety.

For example, IoT-enabled devices can measure temperature, humidity, and vibrations on-site, sending alerts if conditions deviate from safe thresholds. These systems help construction teams act quickly to address risks and maintain project quality.

AI-powered IoT devices go a step further by analyzing collected data to automate decision-making. For instance, machinery equipped with IoT sensors can predict maintenance needs, reducing downtime and avoiding costly breakdowns.

Similarly, wearable IoT technology for workers can track movement and alert managers to potential safety hazards in real time.

The integration of IoT into construction workflows also facilitates smarter resource management. Connected devices can monitor inventory levels, optimize material usage, and track equipment locations to minimize waste and delays. This interconnected ecosystem streamlines project operations, ensuring that resources are used efficiently and projects remain on schedule.

Machine Learning for Decision-Making

Machine learning (ML) systems are designed to learn from data. It does this by leveraging artificial neural networks (ANNs) that mimic the structure of the human brain to identify patterns, make predictions, and streamline decision-making.

In construction, machine learning functions like a smart assistant, searching through vast amounts of data—such as requests for information, open issues, and change orders—to highlight critical insights for project managers.

By analyzing complex and unstructured datasets in real time, ML technology simplifies decision-making and helps teams stay focused on high-priority tasks. Machine learning also underpins advanced safety monitoring, where algorithms analyze real-time data to identify potential dangers before they escalate.

“We can’t overlook the rise of artificial intelligence and machine learning for today’s biggest construction industry trends. We are at an interesting crossroads in the industry where a lot of wasteful processes could be automated using these technologies. In the next five years, AI and machine learning are going to be mainstreamed into the products that we are currently using. In turn, we are going to see both productivity and project outcomes improve.”

—Atul Khanzode, Chief Technology Officer, DPR

The integration of machine learning also sets a new standard for safety, efficiency, and productivity. As this technology continues to evolve, its applications will further empower construction professionals to tackle challenges with precision and foresight.

15 Examples of How to Use AI in Construction

Here are 15 examples of how AI is being used in construction to improve the different phases of the construction lifecycle:

1. Enhanced Site Safety Through AI

Safety on construction sites remains a critical concern, with workers facing significantly higher fatality rates than in other industries. In fact, the construction industry recorded more worker fatalities last year than any other sector. In 2022, 1,069 construction workers lost their lives on the job, equating to a rate of 9.6 deaths per 100,000 full-time workers, according to a Bureau of Labor Statistics.

Fortunately, AI technologies are transforming safety protocols, enabling real-time monitoring and proactive measures to minimize risks and protect workers.

“Worker safety is paramount, and AI is being used to reduce risk and improve safety throughout preconstruction and construction. For example, AI is being used to proactively assess safety hazards in real time via tools that include computer vision for hazard detection, wearable technologies, and proximity warning systems.”

—Wes Collins, Associate Professor, McWhorter School of Building Science, Auburn University

AI-powered cameras and sensors continuously scan AI construction sites for potential hazards. It can scan for unsafe working conditions, malfunctioning equipment, or workers not wearing protective gear.

These systems can flag risks and send immediate alerts to managers and workers, preventing accidents before they occur. For instance, AI algorithms analyze video footage and sensor data to detect signs of instability or mechanical issues, ensuring corrective actions are taken quickly.

Wearable AI tech, like smart helmets or vests, further enhances safety by tracking workers’ locations and monitoring environmental conditions. Integrated SOS buttons and real-time incident reporting features allow quick responses in emergencies, while collaboration platforms keep all stakeholders informed to improve organizational safety.

AI also predicts maintenance needs for critical systems like HVAC and electrical. This helps ensure equipment remains operational and avoids disruptions that could lead to unsafe conditions. Addressing safety challenges with data-driven solutions means AI can help reduce accidents and foster a safer work environment.

2. Construction AI for Design and Planning

AI is transforming the design and planning stages of construction, empowering architects, engineers, and construction professionals with advanced tools to streamline processes and enhance decision-making.

One of the most notable advancements is the integration of AI-powered Building Information Modeling (BIM). BIM is a 3D model-based process that incorporates architectural, engineering, mechanical, electrical, and plumbing (MEP) plans.

Moreover, generative design, powered by machine learning, takes planning a step further. AI algorithms explore countless design alternatives based on predefined constraints like cost, materials, energy efficiency, and regulatory requirements.

Through iterative learning, these algorithms produce optimized 3D models, offering innovative solutions that meet performance and sustainability goals.

AI also plays a critical role in quality assurance during the planning phase. Advanced tools analyze BIM models and designs for potential flaws or inefficiencies, flagging them early so adjustments can be made before construction begins. This proactive approach reduces costly errors and accelerates project timelines.

In addition, AI supports automation in budgeting and resource planning. By analyzing complex data—such as building codes, historical project trends, and zoning laws—AI helps construction companies estimate material requirements and costs with greater accuracy, expediting the bidding process.

“As AI tools advance in 2024, we can expect their deeper integration in the design and planning phases of construction, providing more advanced options for modeling and simulations. There’s a growing trend towards AI-powered automation in construction methods such as prefabrication and modular building.”

—Ian McGaw, Senior Manager, Product Innovation, Global, Vantage Data Centers

3. AI in Project Management

When it comes to AI in project management, advanced AI tools analyze photo and video footage from work sites, offering real-time insights to track progress and crew productivity.

This data-driven approach enables managers to address issues as they arise, adjust timelines based on actual progress, and visualize project stages using 3D models and BIM.

Beyond tracking and forecasting, AI simplifies administrative tasks like budgeting, invoicing, and tracking payments, helping to prevent cost overruns.

“AI will definitely take the construction industry in 2024. AI will be the assistant project manager that predicts problems, offers real-time insights, decision support, and keeps the budgets on track. Equipment powered by AI will be thing, like CCTV AI that predicts the risks in the construction site and maybe wearables that monitors and tracks the team in every move. With the help of generative AI, designs will come straight out with a simple click. And Digital Twins will be integrated with AI that provides automated predictive analysis and modelling and clash detection.”

—Mark Jason Villanueva, Corporate BIM Manager, Newcon Builders Pte. Ltd.

Moreover, AI-powered communication tools, using natural language processing (NLP), facilitate seamless collaboration by translating documents, transcribing meetings, and generating reports.

Lastly, AI-driven collaboration platforms further streamline operations by centralizing schedules, documents, and communications. These systems optimize the allocation of labor, equipment, and materials to ensure resources are used efficiently throughout the project lifecycle.

AI in Project Planning

AI’s role in project planning is just as transformative.

AI-powered drones with advanced imaging technology are being used to capture aerial views of construction sites. These drones collect high-resolution data, which is then analyzed by machine learning algorithms to track project progress and identify discrepancies.

For example, deviations in material placement or structural alignment can be detectable early, allowing project managers to address potential issues before they escalate into costly delays or rework.

Moreover, reinforcement learning, a cutting-edge AI technique, enables algorithms to evaluate endless combinations and optimize workflows over time, improving the accuracy of planning strategies.

Lastly, AI systems break large projects into manageable tasks, streamlining scheduling and resource allocation. Analyzing data from similar projects allows AI to anticipate risks like delays or material shortages, offering mitigation strategies to keep projects on schedule.

4. Predictive Maintenance for Detecting Anomalies

Predictive maintenance, one of the earliest applications of AI in construction, continues to revolutionize equipment management by extending machinery lifespans, improving site safety, and preventing costly downtime.

The process involves AI analyzing sensor data—such as temperature, vibration, and performance stats—to detect anomalies and patterns that indicate potential equipment issues.

For example, it can detect unusual temperature spikes in a bulldozer’s hydraulic system or inconsistent pressure levels in a concrete pump. When anomalies are detected, the system sends alerts to operators, suggesting maintenance actions to prevent potential malfunctions.

This approach not only reduces unexpected breakdowns but also ensures optimal machinery performance, avoiding delays that can disrupt interconnected project tasks.

AI’s role in predictive maintenance goes beyond machinery. It can monitor HVAC and electrical systems on construction sites, identifying potential failures and ensuring uninterrupted operations.

Furthermore, advanced image recognition technology enhances this process, analyzing site photos and videos to detect construction defects and quality control issues that may require intervention.

5. Quality Control With Artificial Intelligence in Construction

Ensuring high-quality construction work is critical but often challenging due to the complexity of modern designs and the limitations of traditional inspection methods. AI is transforming quality control by automating inspections, improving accuracy, and reducing delays, allowing construction teams to meet safety and regulatory standards more efficiently.

AI-powered cameras, drones, and sensors continuously monitor AI construction sites, capturing images and data in real-time. Using advanced image recognition technology, AI systems analyze this data to detect defects, structural weaknesses, or deviations from project specifications.

These tools learn on vast datasets of annotated images, enabling them to identify a wide range of potential issues with precision. For example, AI can flag improper installations or missing structural elements, allowing teams to address problems before they escalate.

AI doesn’t just identify defects; it streamlines the entire inspection process. Drones equipped with AI can capture comprehensive site images in minutes, while software processes the data to pinpoint problems. This eliminates the need for time-consuming manual inspections, enabling quicker responses and reducing project delays.

6. AI in Bidding and Negotiating

Bidding and negotiations are essential yet traditionally labor-intensive stages of construction projects. From estimating project costs to compiling bids from subcontractors, the process has long been a bottleneck for contractors. AI is transforming this phase by streamlining workflows, reducing turnaround times, and improving accuracy.

For trade contractors, AI helps analyze project scopes, identify profitable opportunities, and develop winning bidding strategies. Automated systems evaluate project requirements, vet potential bids, and ensure that contractors prioritize jobs with the highest likelihood of success.

In addition to speeding up estimations, AI enhances the bidding review and negotiation process. With AI tools, project teams can compare bids more efficiently, identify the most competitive offers, and ensure alignment with project goals and budgets.

This data-driven approach enables smarter negotiations, ensuring that contractors and suppliers are selected based on both cost-effectiveness and quality.

7. Mitigating Risks in Construction With AI

Risk is an inherent part of construction projects and larger projects are especially vulnerable, as multiple subcontractors often work simultaneously on interconnected tasks. However, AI is redefining risk management by enabling contractors to identify, prioritize, and address risks efficiently, ensuring smoother and safer operations.

AI solutions use machine learning algorithms to monitor job sites, automatically assigning priority to potential issues based on their severity. For example, subcontractors can be rated using risk scores, allowing construction managers to focus their efforts on high-risk teams and mitigate problems before they escalate.

Moreover, AI enhances safety through computer vision tools that detect hazards in real-time, such as unsafe machine operations or poor site conditions. These tools suggest preventative measures to avert accidents and ensure worker safety.

Additionally, AI-powered scheduling and resource allocation tools help prevent cost overruns by keeping budgets aligned with project requirements.

Long-term risks related to quality are mitigated through AI-automated site inspections and analysis of 3D models and video footage, enabling early detection of defects or deviations from plans. For on-site security, AI outperforms traditional methods by analyzing video feeds 24/7 to flag threats like theft or vandalism, even on large-scale projects.

Predictive analysis powered by AI further streamlines risk mitigation. For example, supply chain management and compliance monitoring tools identify potential delays or regulatory issues, enabling proactive resolutions.

8. Improving Collaboration and Communication With AI

AI-powered tools empower teams working on different aspects of a project to function as a cohesive unit, regardless of location.

Virtual and augmented reality tools backed by AI help with collaboration. These technologies enable team members and stakeholders to visualize project plans remotely, providing a shared perspective and allowing feedback from anywhere in the world.

This is especially valuable for complex projects, where clear communication can prevent costly misunderstandings and delays.

Additionally, AI-powered communication tools, leveraging natural language processing (NLP), further enhance connectivity. These tools can translate documents, transcribe meetings, and even generate reports, breaking down language barriers and ensuring clarity across diverse teams.

For global construction projects, this ensures seamless communication between stakeholders with different linguistic and cultural backgrounds.

9. Sustainability With AI for Construction

Sustainability is a growing priority in the construction industry, and AI is playing a crucial role in helping companies reduce their environmental impact.

“Looking ahead to 2024, sustainability is likely to emerge as a central focus in the integration of AI within construction. As businesses across industries undertake decarbonization efforts to address climate-change targets, the construction sector must respond. AI, with its capacity to analyze complex datasets captured through IoT devices, sensors, and other technologies, offers a practical solution for accurate analysis and predictions. Its potential to optimize resource usage and reduce environmental impact positions AI as a pivotal force in designing and executing environmentally conscious construction projects.”

—Maria Fernanda Olmos, Global Principal Digital Integration, Unispace

First, AI analyzes data on energy consumption, emissions, material use, and other environmental factors to identify opportunities for improvement. For example, AI can recommend ways to optimize energy and water usage during construction, reducing both environmental impact and operational costs.

This data-driven approach helps construction professionals make informed decisions that align with sustainability goals.

AI also supports sustainable practices by improving material efficiency. Algorithms can analyze material requirements and usage patterns to reduce waste, ensuring that resources are used effectively.

Additionally, predictive analysis can forecast the environmental impact of different construction methods, allowing teams to select greener alternatives.

For long-term sustainability, AI can assist in designing energy-efficient buildings by simulating and testing various scenarios to ensure optimal performance.

From minimizing emissions to improving waste management, AI enables construction companies to integrate sustainability into every project phase.

10. Boost Job Site Productivity With AI

Integrating AI solutions into job site operations allows construction companies to achieve faster project completion, improved safety, and better resource allocation.

For example, advanced AI-powered machinery, including self-driving construction equipment, is taking on tasks such as bricklaying, concrete pouring, welding, and demolition with precision and efficiency.

These technologies not only reduce the time required to complete projects but also free up human workers for more complex and skilled construction activities.

AI tools also play a critical role in tracking and improving on-site productivity. Project managers use technologies like facial recognition, real-time video feeds, and onsite cameras to monitor worker performance and adherence to safety protocols.

These systems provide actionable insights, helping teams identify bottlenecks and optimize workflows to stay on schedule.

11. Leveraging AI in Construction to Lower Costs

AI is a powerful tool that can shorten project timelines through automation, significantly cutting labor costs while maintaining productivity. For example, tasks such as bricklaying, site grading, and quality inspections are completed faster and with greater accuracy, reducing the reliance on manual labor for time-consuming activities.

Better planning, powered by AI, further contributes to cost savings. AI tools analyze data from past projects, material usage patterns, and supply chains to optimize the allocation of resources. This ensures minimal material waste and prevents over-ordering, which can lead to unnecessary expenses.

Moreover, predictive analytics also help teams avoid costly delays by identifying potential risks and inefficiencies early in the project lifecycle.

Lastly, AI’s ability to streamline workflows plays a key role in budget management. Automated scheduling and resource allocation ensures that construction tasks are completed on time and within budget.

12. AI-Powered Tools for Construction Documents

Traditionally, handling contracts, blueprints, permits, and project specifications is a time-consuming and labor-intensive process. With AI-powered tools, companies can automate tasks such as document tagging, categorization, and extraction of critical information, saving time and enhancing accuracy.

For example, AI algorithms can analyze large volumes of construction documents to identify key terms, clauses, and data points, making it easier to review contracts or ensure compliance with regulations. Natural language processing (NLP) technology enables these systems to interpret complex text, flagging inconsistencies or risks that might otherwise be overlooked.

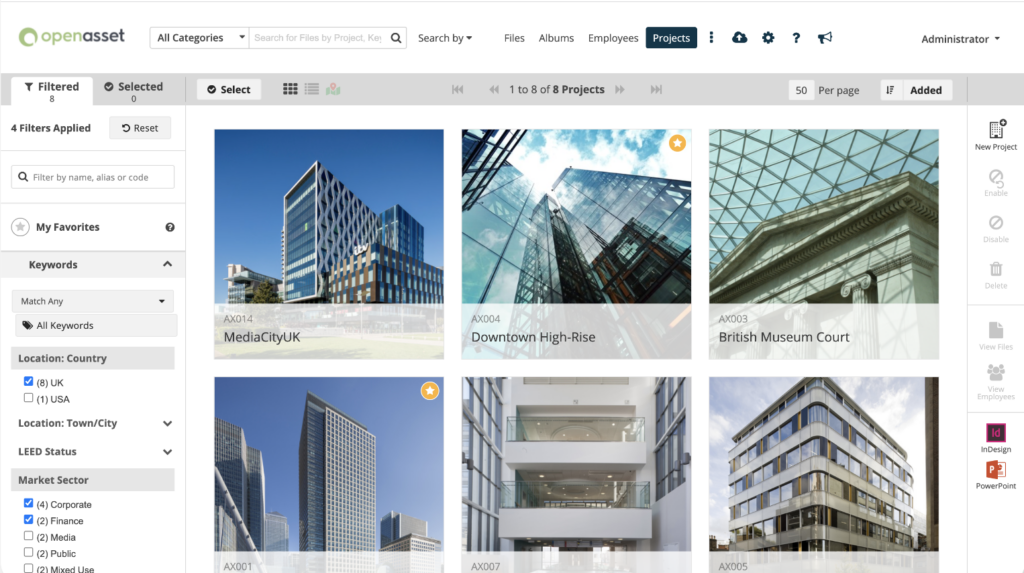

A tool like OpenAsset, digital asset management (DAM) software for AEC professionals, is especially valuable in this context. OpenAsset leverages AI to organize and tag visual assets—such as project images—automatically. This means teams can quickly access the materials they need for proposals, reports, or audits.

Furthermore, AI-driven document management improves collaboration by centralizing all project-related files. Teams can access the latest versions of documents in real time, ensuring everyone works from accurate and up-to-date information. This reduces delays caused by miscommunication and enhances overall project execution.

13. AI Robotics in Construction

AI-powered robotics combines artificial intelligence with advanced machinery to perform complex tasks with precision and adaptability. Unlike traditional automation, these robots use sensors and machine learning algorithms to analyze their surroundings, recognize patterns, and make decisions based on real-time data.

This enables them to learn from experience and adapt to changing conditions, making them invaluable on dynamic construction sites.

AI robots are already playing a crucial role in tasks such as 3D printing, bricklaying, painting, welding, and rebar tying. They are also being used for layout drawing, site monitoring with drones and rovers, and operating heavy equipment autonomously.

Moreover, self-driving trucks and other intelligent machinery further enhance the efficiency of construction workflows.

Importantly, AI robotics is not about replacing human workers but complementing them. Collaborative robots, or “cobots,” work alongside humans to make jobs safer and more efficient. For example, a bricklaying robot can handle the heavy lifting while humans focus on the precision and detail work, reducing physical strain and increasing overall productivity.

“The construction sector is experiencing a paradigm shift. Companies are increasingly recognizing the synergy between AI and human skills, which enhances both productivity and sustainability.”

—Fang Chen, Professor and Executive Director, Data Science Institute, University of Technology Sydney

14. Autonomous Technology in Construction

Autonomous technologies range from heavy machinery to drones, transforming how tasks are completed on job sites. For example, autonomous and semi-autonomous bulldozers and excavators are revolutionizing site preparation and excavation.

Programmed to operate with minimal manual intervention, these machines follow pre-defined specifications to perform tasks with unmatched accuracy and consistency. These technologies not only reduce project timelines but also minimize the risk of human error.

Moreover, drones equipped with AI software are another example of autonomous technology enhancing construction workflows. These drones can capture aerial surveys of job sites and compare the data to blueprints in real-time. This capability helps identify discrepancies or obstacles, allowing project teams to make necessary adjustments without delaying progress.

Additionally, as mentioned earlier, autonomous robots are also being deployed to perform repetitive and physically demanding tasks, such as bricklaying, welding, and material handling.

These machines work with high precision, reducing material waste and improving overall project quality. They can also operate continuously without fatigue, ensuring faster project completion while maintaining consistent standards.

15. Optimizing Resource Allocation With AI in Construction

AI empowers construction companies to manage resources like materials and labor more efficiently. AI analyzes project data to identify areas of waste and recommends strategies to optimize resource use.

For example, AI tools can forecast material needs based on historical data, ensuring accurate ordering and minimizing excess. Similarly, AI-powered scheduling aligns labor allocation with project timelines, avoiding overstaffing or underutilization. This not only reduces costs but also ensures smoother project execution.

AI Construction Tools

“In 2024, AI is on the verge of making remarkable progress. Plan to see more AI-powered tools becoming part of the landscape, providing an opportunity to explore how it can enhance work. Not only will increased AI exposure help improve job performance, but it also eases worries about AI’s complexities. It underscores the importance of gathering data carefully, showcasing how data becomes a powerful tool for competitive advantage.”

—Ariel Castillo, Director of Innovation, Miller-Davis

Here are some AI-powered tools transforming the construction industry:

- OpenSpace: Utilizes 360-degree cameras and AI to automatically capture and map construction site images, creating a comprehensive digital twin for progress tracking and issue identification.

- Procore: A construction management platform that integrates AI to streamline project workflows, improve productivity, and enhance collaboration among stakeholders.

- Fusion 360 by Autodesk: Combines 3D modeling, simulation, and computer-aided manufacturing, leveraging AI to optimize design processes and facilitate collaboration.

- ALICE Technologies: Employs AI to assist construction teams in planning and managing projects more effectively, exploring various scenarios to optimize schedules and resources.

- Doxel: Uses AI-powered robots to monitor construction sites, providing real-time data on progress and quality to ensure projects stay on track.

- Buildots: Integrates AI with wearable cameras to capture site data, automatically analyzing it to detect deviations from plans and schedules.

- Fieldwire by Hilti: Offers a field management platform that utilizes AI to enhance task management, coordination, and communication among construction teams.

- AI Clearing: Provides AI-driven solutions for progress tracking and quality assurance, using drone data to deliver actionable insights.

- OpenAsset: A DAM platform tailored for AEC that uses AI for AI-suggested keywords, image similarity, AI-powered content assist, AI facial recognition, and more. This makes managing and retrieving digital assets faster and more efficient.

The Future of AI in the Construction Industry

The future of AI in construction is incredibly promising as new advancements continue to reshape the industry. In fact, the global Artificial Intelligence (AI) in Construction Market size was valued at USD 610.64 Million in 2021 and is projected to reach USD 5 billion by 2030.

“In 2024, AI in the construction industry is likely to play an increasingly significant role. AI applications may include advanced project management tools, predictive analytics for risk assessment, and optimization of construction processes. AI-driven technologies might also enhance safety protocols through real-time monitoring and analysis. In addition, the use of AI in design and planning stages could lead to more efficient resource utilization and cost-effective solutions. Keeping abreast of AI developments and industry-specific applications will be crucial for stakeholders in the construction sector in 2024.”

—Akshay Barde, Executive – EHS, Oberoi Realty

Emerging technologies such as autonomous machinery, predictive maintenance, and sustainability-driven solutions are paving the way for more innovative and data-driven practices.

Moreover, autonomous robots and drones are already transforming tasks like site surveying, material transportation, and bricklaying. These machines operate with precision and consistency, reducing human error and increasing productivity.

According to Boston Consulting Group (BCG), up to 30% of construction tasks could be automated by 2025, significantly shortening project timelines and boosting labor efficiency.

AI is also revolutionizing maintenance processes. Predictive tools analyze data from sensors to anticipate machinery repairs, transitioning construction firms from reactive to proactive maintenance strategies.

This reduces equipment downtime, lowers repair costs, and extends the lifespan of critical assets, ensuring uninterrupted operations on site.

Sustainability is another area where AI is making significant strides. As climate concerns grow, AI-powered tools are helping construction companies optimize material usage, reduce waste, and design energy-efficient buildings.

In addition to physical tasks, AI is enhancing project collaboration and communication. Future AI platforms are expected to automate administrative tasks like scheduling and reporting, while advanced natural language processing will make interacting with AI systems more intuitive for team members.

As the construction industry embraces AI, its potential to drive innovation, improve operations, and deliver sustainable solutions will only grow. Early adopters of AI technologies will position themselves as leaders in a rapidly evolving market, shaping the future of construction.

“As everyone is saying, AI is here, and AI is here to stay. In 2024 we will see a tremendous amount of investments, new ideas, and trends in the industry. There is so much potential to be gained with utilizing AI to solve issues. As technology leaders, it is critical that we focus on prioritizing to solve root cause issues within our collective organizations.”

—Brad Buckles, VP of Technology and Innovation, Charles Perry Partners, Inc.

FAQs: Using AI in Construction

If you still have additional questions, here are the top FAQs to provide further insight:

How is AI used in construction?

AI is used in construction to optimize workflows, improve safety, and enhance decision-making. Applications include predictive maintenance, real-time site monitoring, automated machinery, generative design, and resource management. AI also analyzes data to identify risks, streamline scheduling, and ensure quality control throughout the project lifecycle. The possibilities are endless.

How do you use AI in construction estimating?

AI simplifies construction estimating by automating takeoffs and analyzing project data. Tools powered by machine learning detect and measure spaces on blueprints, generate cost estimates, and assess material needs with precision. This reduces the time required for bidding and ensures more accurate, competitive proposals.

How can AI help construction companies get more business?

AI can help construction companies get more business by streamlining proposals, optimizing marketing efforts, and improving project delivery. Tools with AI-powered features, tailored to AEC professionals, like OpenAsset can enhance proposals by efficiently organizing and tagging visual assets, making it easier to showcase past projects in a professional, visually compelling way. With better resource management and polished marketing materials, AI empowers construction companies to stand out in a competitive market and win more business.

What are the key benefits of implementing AI in construction projects?

While the list of benefits from AI in construction can go on and on, here are a few of the top benefits:

- Reduced costs

- Faster project timelines

- Improved safety enhanced quality control

- Better resource allocation

- Risk mitigation

- Predictive analytics

- Fosters collaboration through real-time data sharing

How can AI improve the efficiency and safety of construction sites?

AI boosts efficiency by automating repetitive tasks, optimizing resource use, and providing real-time insights into project progress. For safety, AI-powered sensors, drones, and cameras monitor job sites to detect hazards, predict equipment failures, and alert managers to potential risks before accidents occur.

What types of AI technologies are commonly used in the construction industry?

Common AI technologies in construction include:

- Machine learning for predictive analytics

- Computer vision for defect detection

- Generative design for optimizing building models

- IoT for real-time monitoring

- Autonomous machinery and AI-powered collaboration platforms for enhancing efficiency and accuracy

How does AI help in managing construction project timelines and budgets?

AI helps manage timelines and budgets by forecasting potential delays, optimizing schedules, and automating resource allocation. Predictive analytics identify risks early, while cost estimation tools ensure accurate budgeting. These capabilities keep projects on track and reduce the likelihood of overruns.

What are some common challenges faced when integrating AI into construction workflows?

Challenges include high implementation costs, lack of technical expertise, and resistance to change within teams. Additionally, integrating AI tools with existing systems and ensuring data accuracy can be complex. Overcoming these hurdles requires training, planning, and investment in scalable AI solutions.

How can small construction firms benefit from AI?

Small firms can leverage AI for cost-effective solutions like automated scheduling, material optimization, and safety monitoring. Affordable AI tools reduce overhead and improve efficiency, allowing smaller companies to compete with larger firms.

Is AI replacing human workers in construction?

AI complements human workers by automating repetitive tasks and enhancing decision-making. It doesn’t replace humans but supports them in performing complex and skilled work more effectively, fostering safer and more efficient job sites.

What is the future of AI in construction?

The future of AI in construction includes advancements in autonomous machinery, predictive modeling, and sustainability solutions. Emerging technologies will further enhance collaboration, efficiency, and eco-friendly practices, transforming the industry.

Embrace the Future of AI Construction With OpenAsset

Artificial intelligence is no longer a futuristic concept—it’s a transformative force reshaping the construction industry today. From streamlining workflows and improving safety to enhancing collaboration and sustainability, AI is driving innovation at every stage of the construction lifecycle. As businesses adapt to this technological shift, the ability to effectively manage and leverage digital assets becomes critical to staying competitive.

OpenAsset— DAM tailored to the AEC industry— empowers construction companies to embrace the future of AI with confidence. With AI-powered tools for organizing, tagging, managing visual assets, and more, OpenAsset streamlines operations and enhances project presentations, making it easier to secure new business and deliver exceptional results. With OpenAsset, you’re not just taking a step forward in adopting AI—you’re unlocking its potential to propel your AEC projects and business into the future.